Categories

Tags

-

#China Aluminum Die Casting Products

#China Lead Die Casting

#OEM Aluminum Enclosure

#China Die Casting Factory

#Die Casting Manufacturer

#Lead Die Casting

#Zinc Die Casting

#OEM Aluminum Die Castings 、OEM Aluminum Enclosure

#Zinc Die Casting Chinese Zinc Die Casting Manufacturer

#OEM Aluminum Die Castings

#Aluminum Die Casting China Aluminum Die Casting Products

#aluminum die casting China die casting factory

#China die casting factory aluminum die casting

#OEM aluminum enclosure Die casting manufacturer

#zinc die casting lead die casting

#lead die casting zinc die casting

#China lead die casting China zinc die casting manufacturer

#China lead die casting China zinc die casting manufacturer

#China zinc die casting manufacturer China lead die casting

#lead die casting zinc die casting

#China zinc die casting manufacturer China lead die casting

#China lead die casting China zinc die casting manufacturer

#aluminum die casting China die casting factory

#China die casting factory aluminum die casting

#Die casting manufacturer OEM aluminum enclosure

#lead die casting zinc die casting

#China lead die casting China lead die casting factory

#aluminum die casting China die casting factory

#zinc die casting lead die casting

#China lead die casting China lead die casting factory

#Die casting manufacturer OEM aluminum enclosure

#aluminum die casting China die casting factory

#Aluminum Die Casting

Archives

Why Does OEM Aluminum Enclosure Have Cold Water Barrier

-

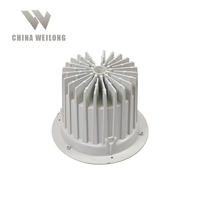

Cold water-blocking defect of OEM Aluminum Enclosure is also called cold water-blocking defect, which is characterized by small metal flows butting each other but not fusing, showing irregular linear shape, which can be divided into two types: penetrating and non-penetrating, and has a development situation driven by external force.

The causes of cold water barrier are: the temperature of molten metal is too low or the mold temperature is too low; The alloy composition does not meet the requirements, and the fluidity is poor. The molten metal is filled in shares and the fusion is not good; The gate is not suitable and the process is too long; The filling speed is too low or the exhaust gas is not good; Low specific pressure.

The method to remove the cold water barrier is to properly raise the pouring air temperature and mold temperature; Adjust alloy composition to improve fluidity; When adjusting the pouring system and increasing the inner gate, improve the filling conditions; Improve discharge overflow conditions and increase overflow volume; Improve injection speed and exhaust conditions; Raise the specific pressure.

Measures must be taken to remove the cold water barrier defects in OEM aluminum enclosure die casting process, so as not to affect the quality and normal use of die casting parts.

We are also a professional China Zinc Die Casting Manufacturer, if necessary, please click our website: https://www.chinaweilong.cn/