Categories

Tags

Archives

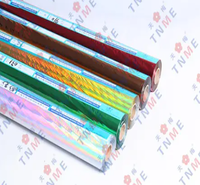

Perfect Hot Stamping Effect

-

The primary task of the hot stamping process is to select the hot stamping foil. The nature of the hot stamping foil adhesive layer determines its adaptability to the product material. If the bronzing paper is not selected properly, any adjustment of the bronzing process will be futile. The hot stamping foil will be officially produced after passing the test.

The perfect hot stamping effect mainly depends on the temperature, pressure, and hot stamping time.

Hot stamping temperature:

The hot stamping temperature is the temperature at which the hot melt water melts to generate the adhesive force. If the hot stamping temperature is too high, the metal layer in the hot stamping paper will be invaded by the color protective layer and oxidized, losing the metallic luster, and the edges of the small text are easily blurred. The sharpness is reduced; the hot stamping temperature is too low, the hot sol cannot reach the molten state, the adhesion between the graphic and the substrate is poor, and the edge of the text may fall off cleanly, and the graphic and text are incomplete. Even if the release agent is not completely dissolved, the transfer layer is difficult to transfer.

Stamping pressure:

For hot stamping on the surface of the paper, because the paper is soft, it is easy to automatically compensate for the problems caused by uneven pressure. As long as the hot stamping temperature is set correctly, the hot stamping pressure does not need to be too large. If the hot stamping pressure is too large, it is easy to cause graphics and text Deformation, the hot stamping pressure is too small. Quality assurance.

Hot stamping time:

For the flat pressing and hot stamping process, the time from pressing the hot stamping device for hot stamping to lifting up to complete the hot stamping can be adjusted. On the premise of ensuring the quality of the hot stamping, the long hot stamping time means that the hot stamping material and the hot stamping paper are not separated. The increase of the contact time is more conducive to the complete penetration of the surface of the substrate by the hot sol, and the adhesion is improved. The relationship between hot stamping time and temperature should be carried out according to the following principles: the hot stamping temperature for large areas of graphics and text is higher, the stamping time can be longer, and the hot stamping temperature for small text and graphics can be higher, but the stamping time Could be shorter.

Zhejiang (Shanghai) TNME Printing Material Co., Ltd. is a Paper Foil Manufacturersturer. Its main products are Plastic Foil and other related products. Welcome to consult and guide!