Categories

Tags

-

#Aluminum Solid Panel

#Metal Composite Panel

#Color Coated Aluminum Coil

#Aluminum Composite Panel

#Fire-resistant Aluminum Composite Panel

#Aluminum Composite Panel Manufacturers

#Stainless Steel Composite Panel

#Aluminum Honeycomb Panel

#Galvanized Steel Composite Panel

#Signage Aluminum Composite Panel

#Aluminum Corrugated Panel

#Metal Composite Panel Stainless Steel Composite Panel

#Galvanized Steel Composite Panel Signage Aluminum Composite Panel

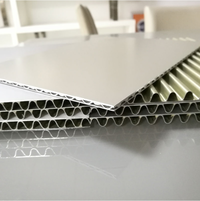

#Aluminum Corrugated Panel Aluminum Honeycomb Panel

#Aluminum Corrugated Panel Aluminum Honeycomb Panel

#Aluminum Composite Panel Manufacturers Aluminum Solid Panel

#Aluminum Solid Panel Color Coated Aluminum Coil

#Aluminum Composite Panel Manufacturers Aluminum Solid Panel

#Metal Composite Panel Stainless Steel Composite Panel

#Metal Composite Panel Stainless Steel Composite Panel

#Aluminum Solid Panel Suppliers

#Aluminum Solid Panel Manufacturers

Archives

Aluminum Composite Panel Is Different From Other Decorative Mat

-

Characteristics of Aluminum Composite Panel: aluminum alloy panel can be processed into various complex graphic shapes such as parallel surface, arc shape and spherical surface by adopting the process of first processing and then painting. Excellent electrostatic powder spraying technology promotes uniform adhesion and distribution between paint and aluminum alloy panel, with the same color, large selection space, uniform distribution of metal coating and various colors. Good aging resistance and corrosion resistance. The aluminum composite panel does not need to be cut and fixed on the skeleton diagram at the extrusion molding construction site of the processing plant. Recycling is beneficial to environmental protection. The recovery of aluminum composite panel is different from the high depreciation rate of decorative building materials such as glass, marble, porcelain and aluminum-plastic panel.

Let's talk about the use of aluminum composite panel:

1. Profiles for aerospace engineering: used to make airplane skins, shell frame structures, beams, rotors, airplane propellers, electronic mail boxes, wall panels and landing gear supports, rocket segment rings, spacecraft wall panels, etc.

2. Profile for Electronic Devices and Household Appliances: Mainly used in various industries such as busbar, stringing, electrical conductor, electrical components, freezer, cable, etc. Aluminum-platinum low alloy panel for air conditioner has good performance, high compressive strength and good ductility, reaching the level of imported products of the same kind.

3. Profile for Packaging: The aluminum coke bottle can material is a mark considering the aluminum processing level of a country. The profiles are mainly in the form of thin panels and foils as metal packaging materials, which are made into cans, lids, bottles, barrels and outer packaging foils.

4. Decorative engineering profiles: aluminum alloy profiles are widely used in building structures, aluminum alloy doors and windows, ceiling ceilings, decorative surfaces, etc. due to their good corrosion resistance, sufficient compressive strength, good industrial and agricultural performance and welding performance.

5. Profile for Packaging and Printing: The printing industry bid farewell to "lead and fire" and stepped into the era of "light and electricity". Aluminum composite panel has provided strong support for the transformation of the printing industry.

Color Coated Aluminum Coil is also one of our product, welcome to buy and purchase!