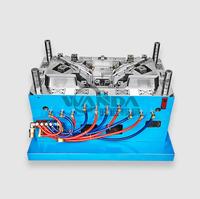

Parts of Custom Auto Parts Mould

-

Posted by mould wanda - Filed in Technology - #Custom Auto Parts Mould #Custom Auto Parts Mould Suppliers #Custom Auto Parts Mould Manufacturers - 33 views

According to the role of each part on the injection mold of Custom Auto Parts Mould, it can be subdivided into the following parts:

(1) Molded parts

A molded part is a part that defines a cavity in a designated movable part. It usually consists of die punch (mold core), die cavity, inserts, etc.(2) Pouring/feeding system of injection mold

The gating system is the channel through which the molten plastic flows from the nozzle of the injection molding machine into the mold cavity. It is composed of main fold, runner, gate and cold material hole.(3) Guiding mechanism of injection mold

The guide mechanism is divided into two types: the guide mechanism between the movable mold and the fixed mold and the guide mechanism of the ejection mechanism. The former is to ensure the accurate centering of the movable mold and the fixed mold when closing the mold, so as to ensure the accuracy of the shape and size of the plastic part.(4) Demolding mechanism of injection mold

A device that takes out the plastic parts from the mold when the mold is opened, also called ejector mechanism. The structure includes ejector release mechanism, push plate release mechanism, push tube release mechanism and so on.For more product-related information, please click: Plastic Mould Suppliers